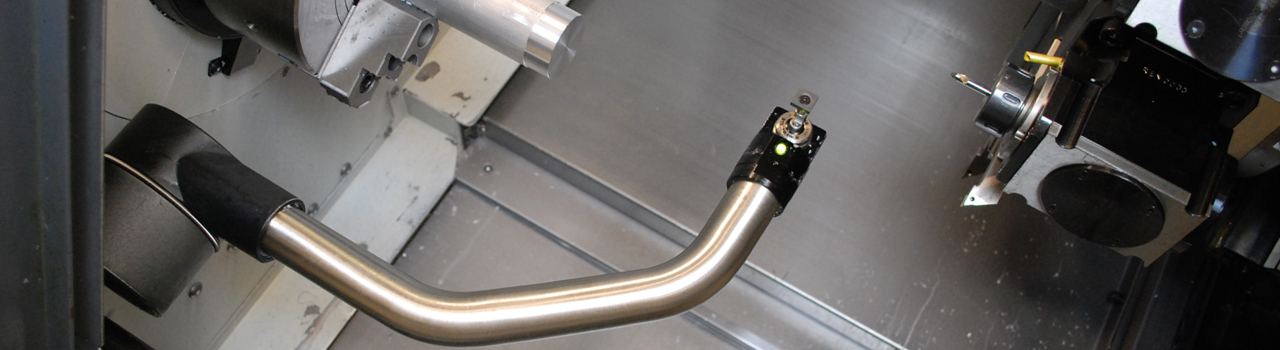

HP arms and RP3 tool

HPMA arms and RP3 tool setting probe

For tool measuring and broken tool detection on 2-axis and 3-axis CNC lathes.

HPRA

High-precision removable arm

A ‘plug-in’ arm which is manually placed in the machine when tool setting is performed, and removed once the process is completed.

HPMA

High-precision motorised arm

An electrically powered arm. Rapid actuation allows in‑process tool setting and broken tool detection without the need for operator intervention.

HPPA

High-precision pull-down arm

The HPPA uses an innovative rotary device which automatically locks the arm into a repeatable kinematic location, with no additional adjustment or locking device required.

HPGA

High-precision generic arm

A highly repeatable motorised solution for tool setting and workpiece inspection with improved robustness and adaptability on grinding machines and CNC lathes.

RP3 tool setting probe

Tool setting kinematic probe for lathes and turning centres that can also be used for workpiece set-up. Suitable for OEM installation into purpose-built holders. It utilises a universal M4 stylus mounting, allowing the full range of Renishaw styli to be used. Connection from the probe terminals to the interface cable is made easy with the availability of an OEM kit. The short body provides significant advantages in tool setting applications and the high performance of traditional Renishaw touch-trigger probes.

RP3 features and benefits

- Compatible with the full range of Renishaw M4 styli.

- Standard fit HP series tool setting arm (HPRA, HPPA and HPMA).

- Flexibility – kit available for OEM installations.

- Large 9° of overtravel – increases the durability of the probe.

- 1.00 μm 2s repeatability.